ZEIUS Bike Carbon Fiber 3D Printed Saddle Seat 174g Ultra Light Breathable Comfortable Saddle MTB Road Bike Ergonomic Racing Carbon Cushion

(0

reviews)

Estimate Shipping Time:

3 Days

Price:

$178.20

/Pc

Refund:

Share:

Sold by

Jennifershop

21/F, China Mansion, 10-18 Des Voeux Road Central, Central and Western District, Hong Kong SAR

(0

customer reviews)

Top Selling Products

- Features

- 1. 3D printing 2. Ultra-light 174g 3. Ergonomic design 4. Full carbon fiber 5. Comfort/shock absorption/heat dissipation

Zone Shock Absorbing Ribbon Cushioning

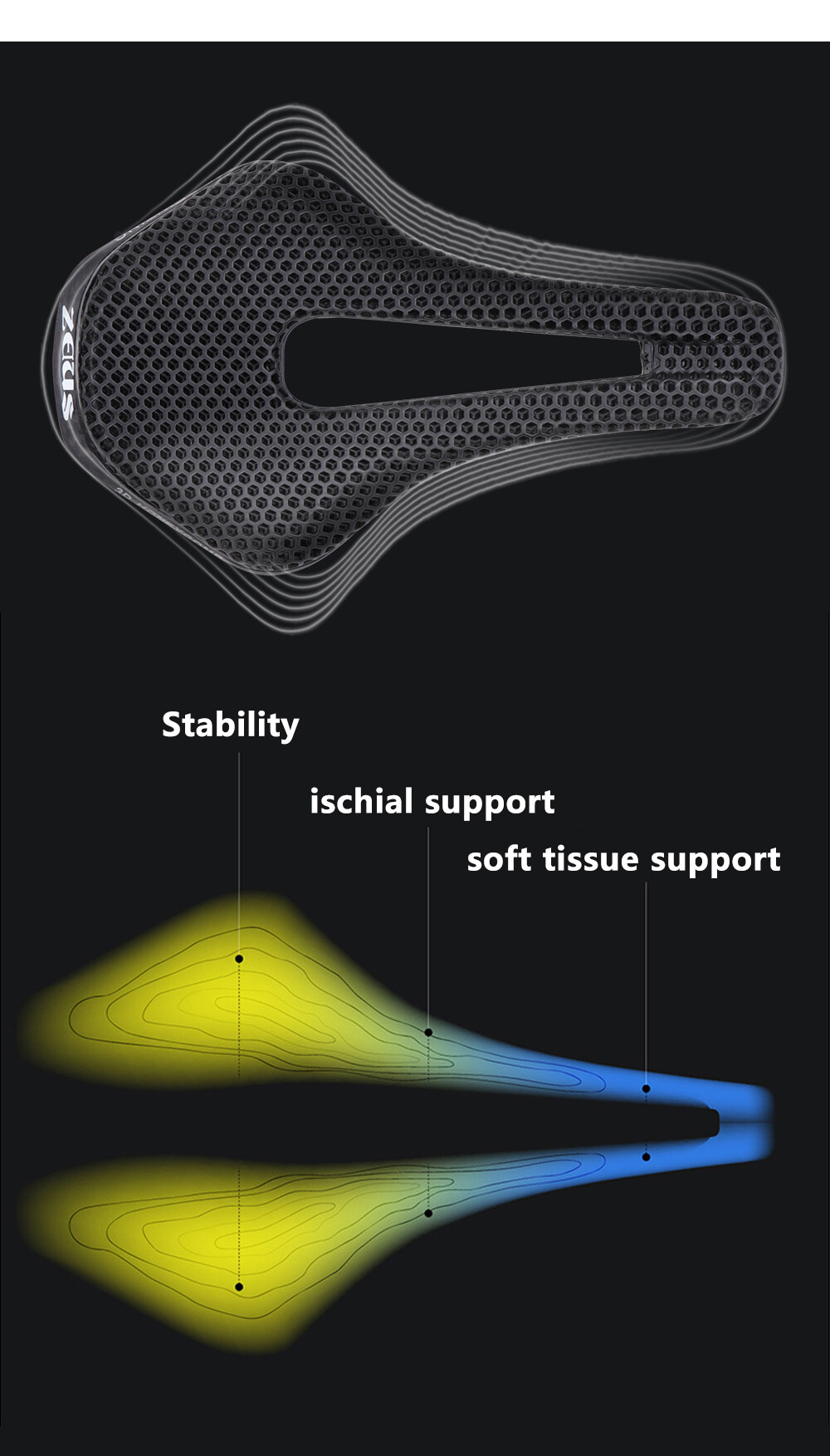

Multiple functional zones are designed and manufactured within the saddle, each tuned to its mechanical properties. Each key functional area is designed with a unique cushioning and mechanical response that seamlessly unites the different areas within the same pad.

Multiple functional zones are designed and manufactured within the saddle, each tuned to its mechanical properties. Each key functional area is designed with a unique cushioning and mechanical response that seamlessly unites the different areas within the same pad.

Ergonomic Design

The honeycomb structure is 3D printed with carbon composite material, instead of the traditional closed-cell foam, which can effectively prevent ultraviolet aging, and the wear resistance is significantly improved compared with the traditional seat cushion.

The honeycomb structure is 3D printed with carbon composite material, instead of the traditional closed-cell foam, which can effectively prevent ultraviolet aging, and the wear resistance is significantly improved compared with the traditional seat cushion.

carbon fiber base

Carbon fiber base + marked slide rails, ultra-light and high strength, weighing only about 162g marked slide rails, always remember your riding habits.

Carbon fiber base + marked slide rails, ultra-light and high strength, weighing only about 162g marked slide rails, always remember your riding habits.

3D printed filling

Not limited by traditional production methods and materials. The adaptive saddle pads are made by CARBON using digital light synthesis technology. DLS is an additive manufacturing process that uses digital UV light projection, oxygen permeable optics and programmable liquid resins to produce parts with excellent mechanical properties, resolution and surface finish.

Not limited by traditional production methods and materials. The adaptive saddle pads are made by CARBON using digital light synthesis technology. DLS is an additive manufacturing process that uses digital UV light projection, oxygen permeable optics and programmable liquid resins to produce parts with excellent mechanical properties, resolution and surface finish.

There have been no reviews for this product yet.

![[SG SELLER] COOLER BOX WITH ROLLER WHEELS PERFECT FOR AN OUTDOOR GET AWAY AVAILABLE IN 28L, 38L, 55L AND 80L](https://www.shopcookserve.com/public/download/p/cce41ed3b24db2294feedca0117d2c82.jpg)